Wastewater treatment

The protection of our rivers, lakes, the fauna and flora, the removal of odours and the protection of the environment in general is a duty for the authorities and a challenge for the companies who work with them.

It is in this field that we have worked hardest and in which we can trul say that we have done almost everything.

Currently, we treat the waste produced by the equivalent of over 15 million people, with over one hundred projects, where we have applied practically all known physical, chemical and biological processes.

With the passing of time and since the first urban waste water treatment plants using biological methods for the removal of carbonaceous material were developed , we have been solving much more complex problems, either through having to treat waste water of a highly industrial nature, due to the development of the country or through the change in the quality levels demanded. In particular, the joining to the European Directive of May, 1991, forced us to design plants with advanced methods for removing nutrients, applying the latest generation in biological processes.

The Research and Development carried out by aqualia infraestructuras, in programmes of experimentation at pilot plants, and the collaboration with specialized engineering companies of international prestige have provided us with the experience needed to solve the problems with highly diversified technologies.

For example, we have used circular and rectangular settlement tanks, with scrapers conventional collection or by suction but have also used lamellar settlement tanks in primary treatment (Mar Menor-Sur WWTP in Murcia); we have built a lot of 18 biological plants for removing carbonaceous material, with several types of aeration systems, using different layouts depending on the problem (complete mix or piston flow, carrousel, contact-stabilisation, with high, medium and low F/M, etc.), we also have plants with two steps biological treatments (Barranco Seco WWTP, Mataró WWTP, Benquerencia WWTP, Velilla WWTP and others), or with soft technologies with biological filters.

We should highlight all the plants at which nutrients are removed, especially those in which it is done using a biological treatment such as the WWTP for Sabadell with a JOHANNESBURG process or the one in Boadilla with a PHOREDOXmprocess and support for sludge fermentation for the enhance of biological nutrients removal. In the field of sludge treatment, we have advanced in line with the progress in the different technologies and at our plants we have used different methods for thickening (gravity, flotation, centrifugation), aerobic digestion with air or with oxygen ( Velilla WWTP in Madrid), anaerobic digestion (over twenty plants), dewatering using centrifuges, belt filter presses, thermal dewatering (Llobregat WWTP and San Sebastián WWTP), sludge incineration (Pinedo WWTP in Valencia and the Córdoba WWTP).

Our experience in this field is supported by over a hundred plants in operation that treat from 420,000 m3/day ( Baix Llobregat WWTP in Barcelona), 410.000 m3/day (Sur WWTP in Madrid), 285,000 m3/day (La China WWTP, Madrid),, or 185,000 m3/day (Pinedo WWTP, Valencia) , down to small plants in rural areas with soft technologies.

W.W.T.P. Baix Llobregat (Barcelona, Spain)

ExpandName: Wastewater treatment plant of Baix Llobregat

Client: DEPURBAIX. S.A.

Situation: Barcelona (Spain)

Start-up: 2004

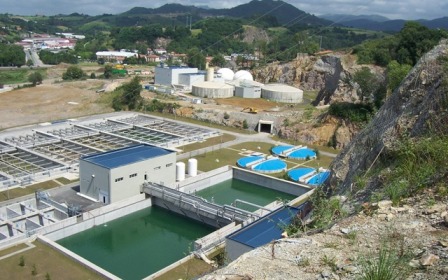

W.W.T.P. Loiola-San Sebastián (Guipúzcoa, Spain)

ExpandPlant Name: Wastewater treatment plant of Loiola - San Sebastián

Client: Ministerio del Medio Ambiente - C.H. del Norte

Situation: San Sebastián (Spain)

Start-up: 2006

W.W.T.P. Cuenca Alta del Arroyo Culebro (Madrid, Spain)

ExpandName: Wastewater treatment plant of Cuenca Alta del Arroyo Culebro - Madrid

Client: Ministerio del Medio Ambiente

Situation: Madrid (Spain)

Start-up: 2006